Home /

Capabilities

At Heiden, Inc. we manufacture metal fabricated parts from prototypes/PPAP's to medium volume production parts. We are backed by over 50 years of industry experience and an ISO 9001:2015 certification. Lead times average 2 to 5 weeks, with rush services available.

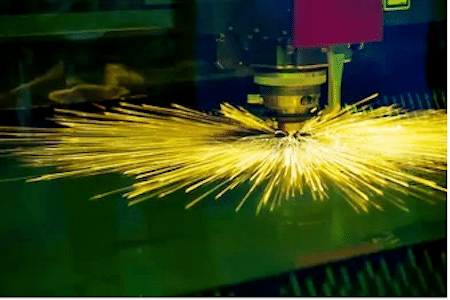

Laser Cutting

- Cut 22ga. to 3/4” thick material

- Sheet size up to 60” x 120”

- Runs “Lights Out”

Punching

- Punch 22ga. to 1/4" thick material

- Sheet Size 60” x 120”

- Runs "Lights Out"

Welding

- Manual & Robotic Mig &Tig

- Resistance

- Steel, Aluminum, Stainless

Bending

- 60, 90, 135, 175 Ton

- Up to 10’ wide parts

- CNC 6 – Axis Backgauges

Inserting

- Haeger 824 Window Touch Inserter with Auto-Feed

- Auto-Sert AS-7.5 Press Inserter

- 1000’s of in-stock self-clinching studs and nuts (steel, Stainless Steel, Aluminum and Brass)

- Atlas Blind Treaded Inserts and Studs (SpinTite, MaxTite and Plus+Tite fasteners)

Assembly

- Dedicated personnel

- Use of wide variety of material

- Including casters, hinges, fittings, velcro, foam, adhesives, stickers and more

REQUEST A QUOTE TODAY